Watch Industry

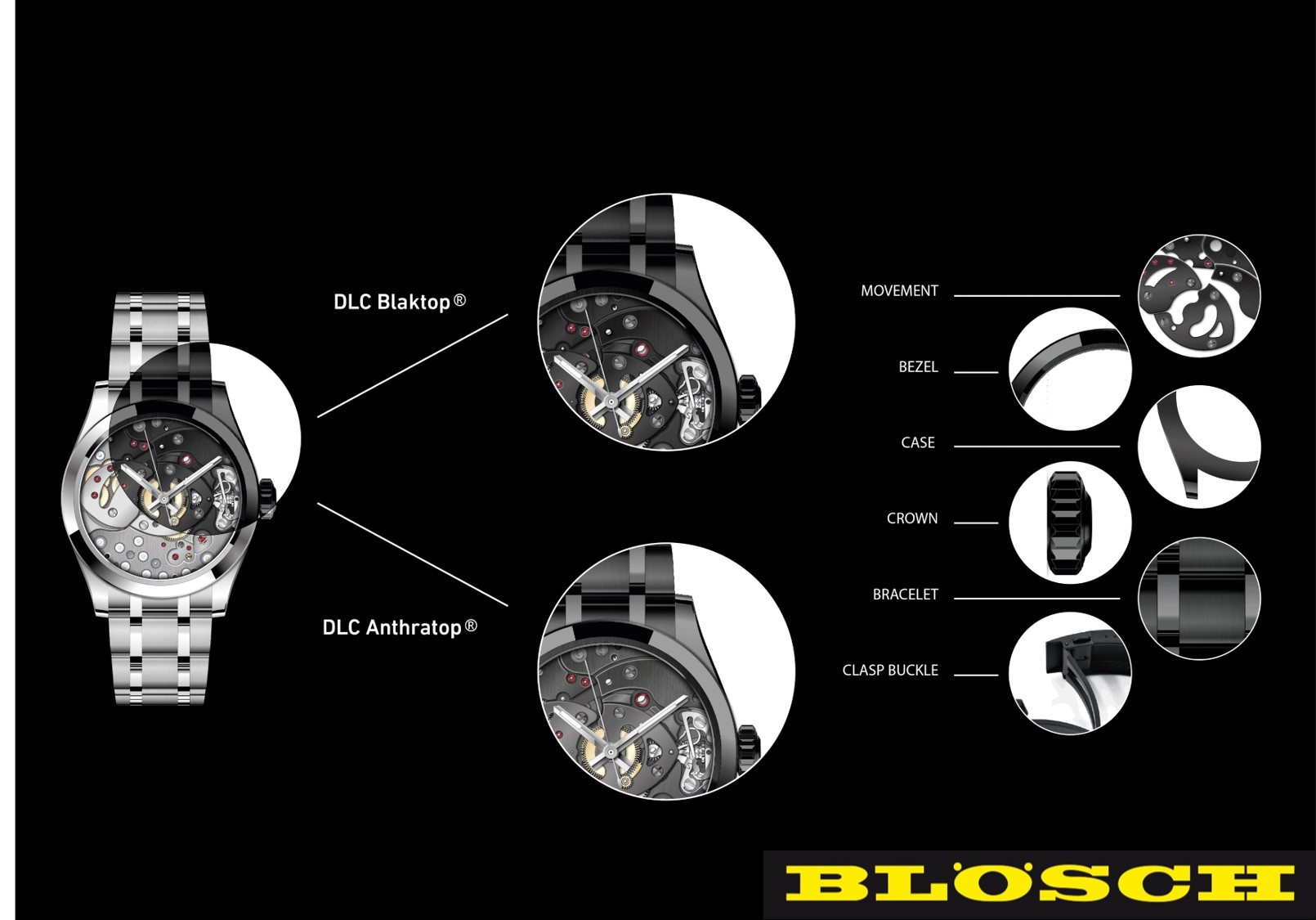

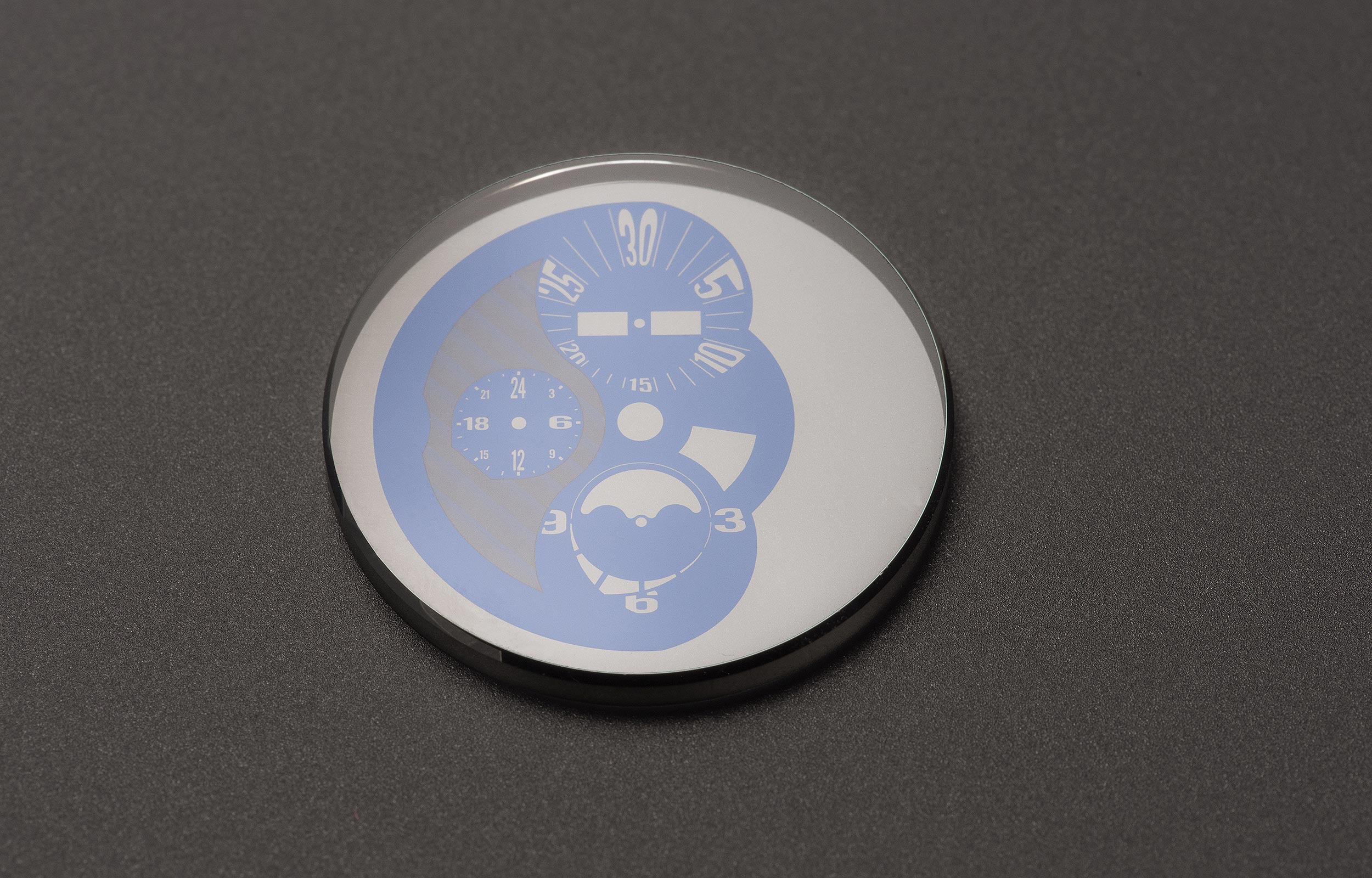

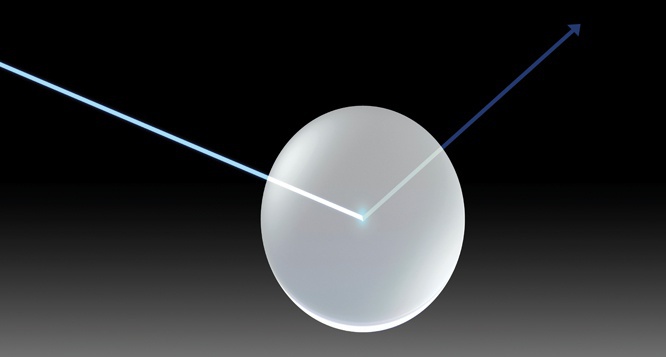

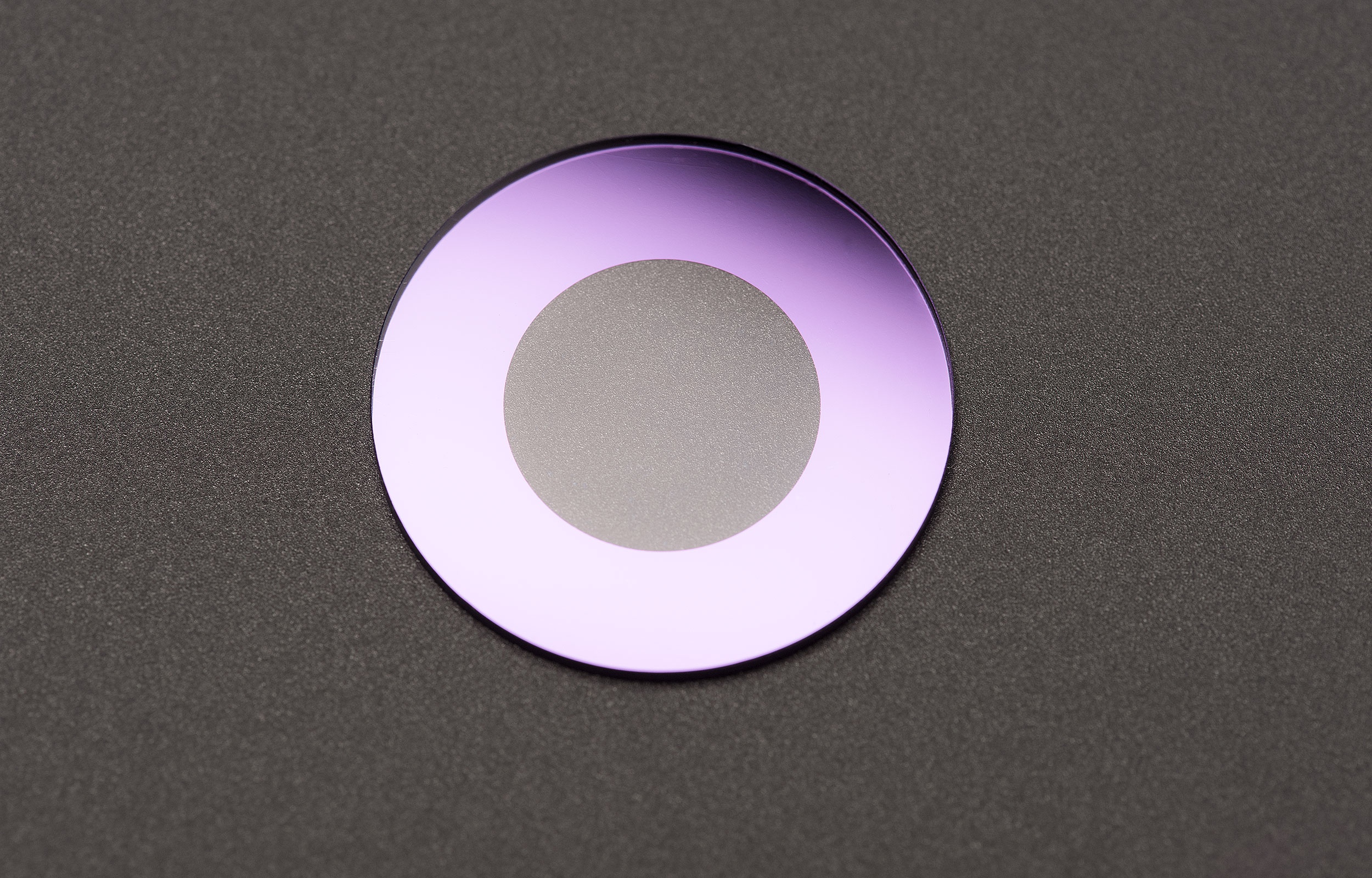

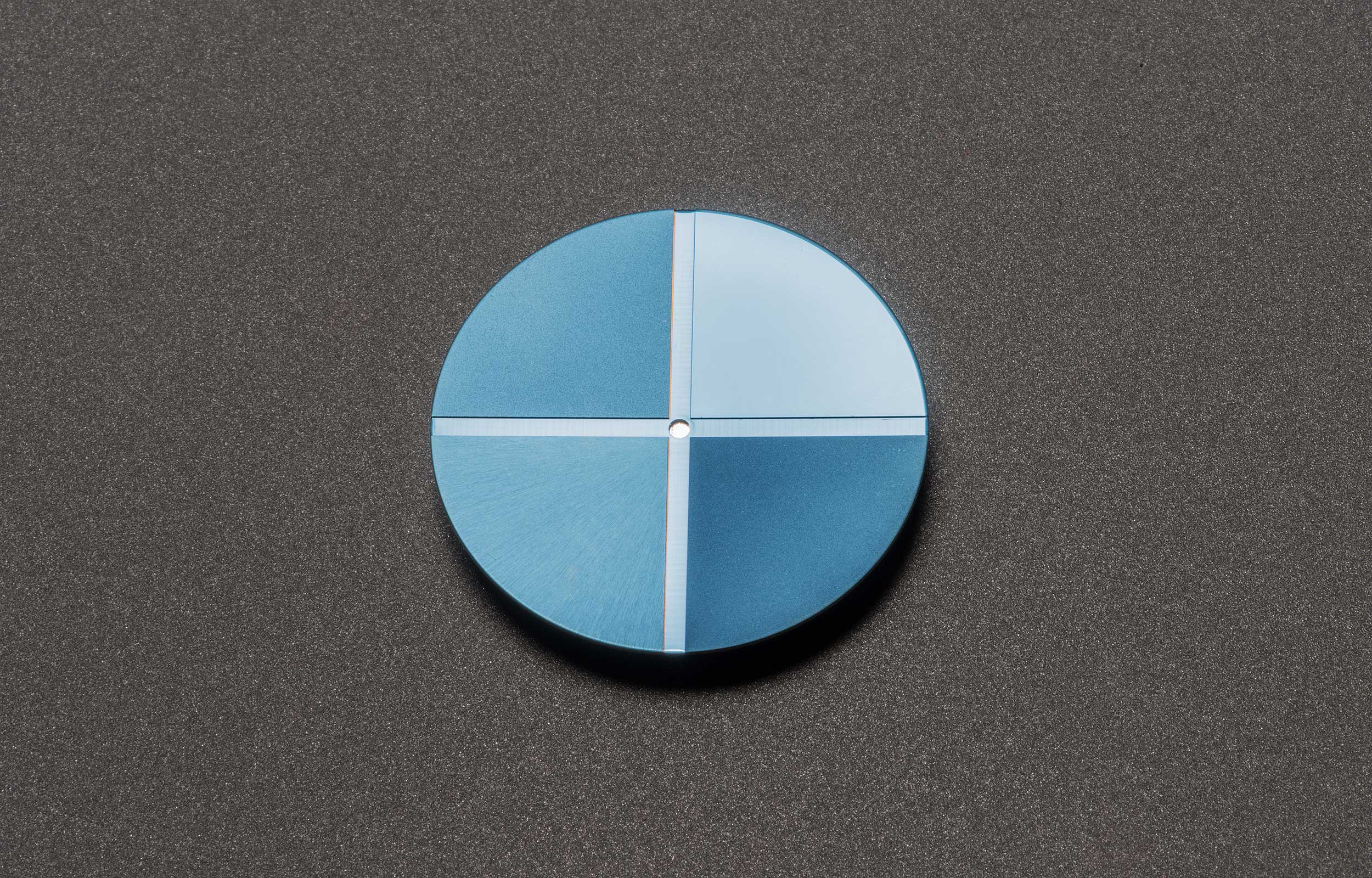

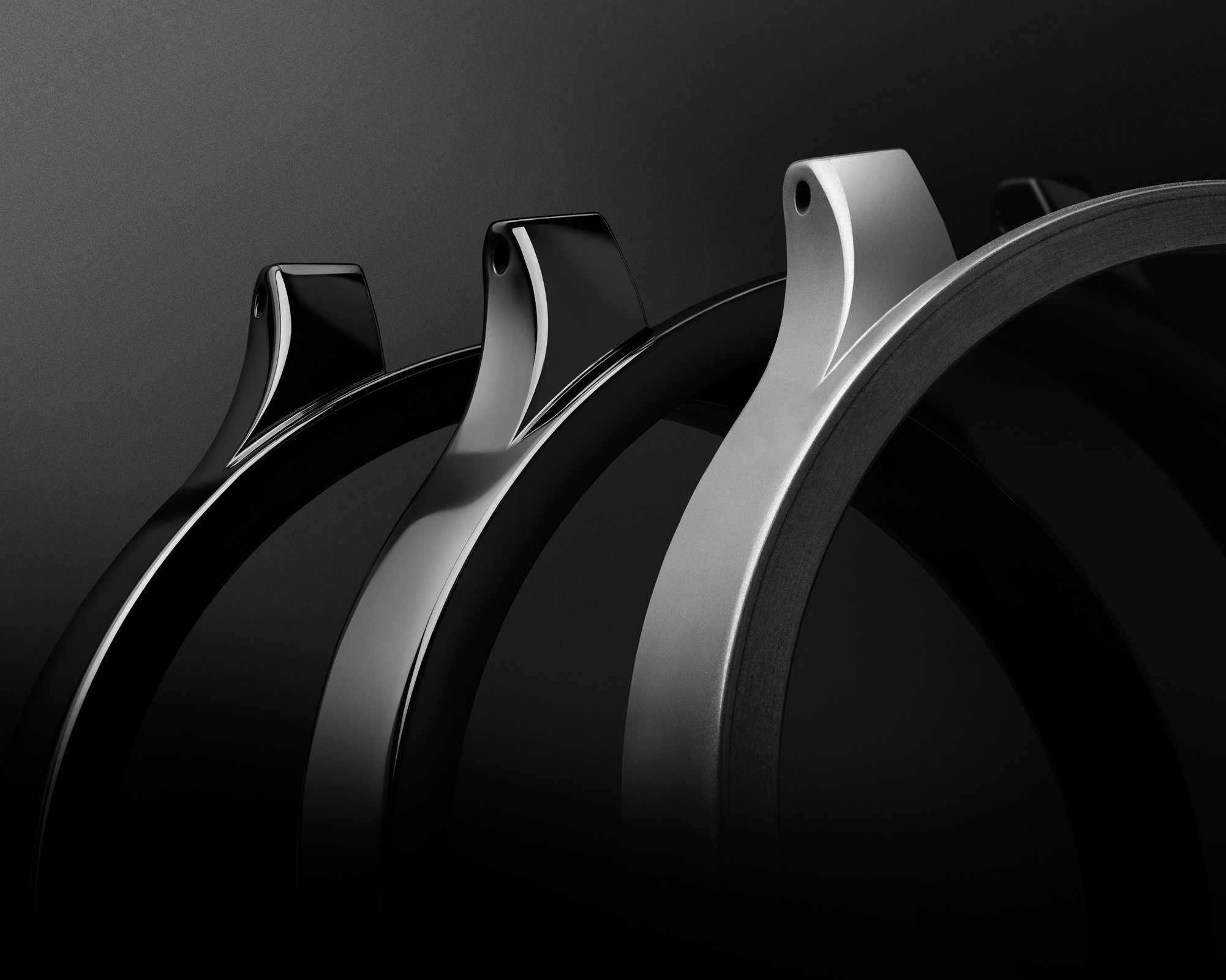

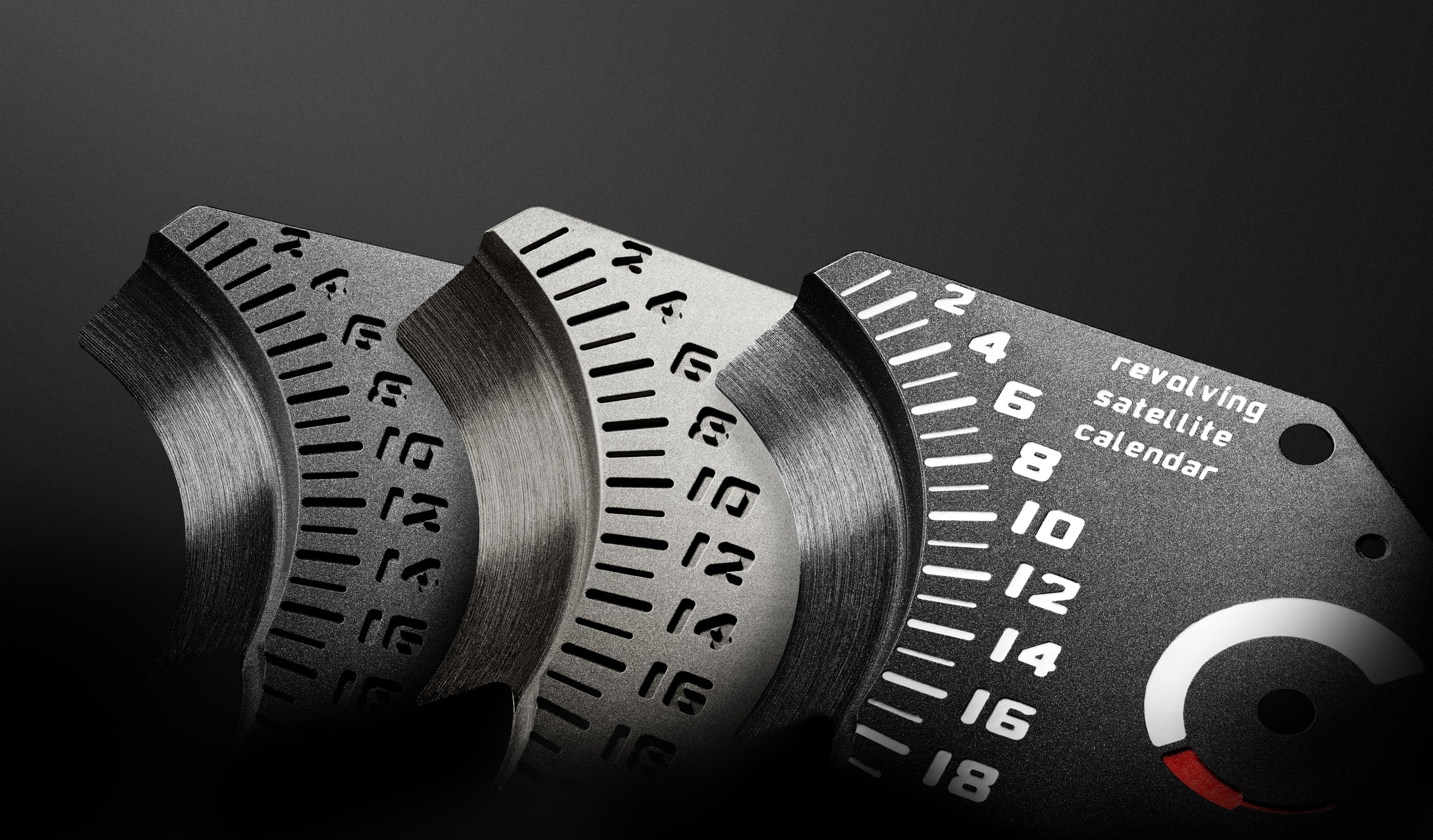

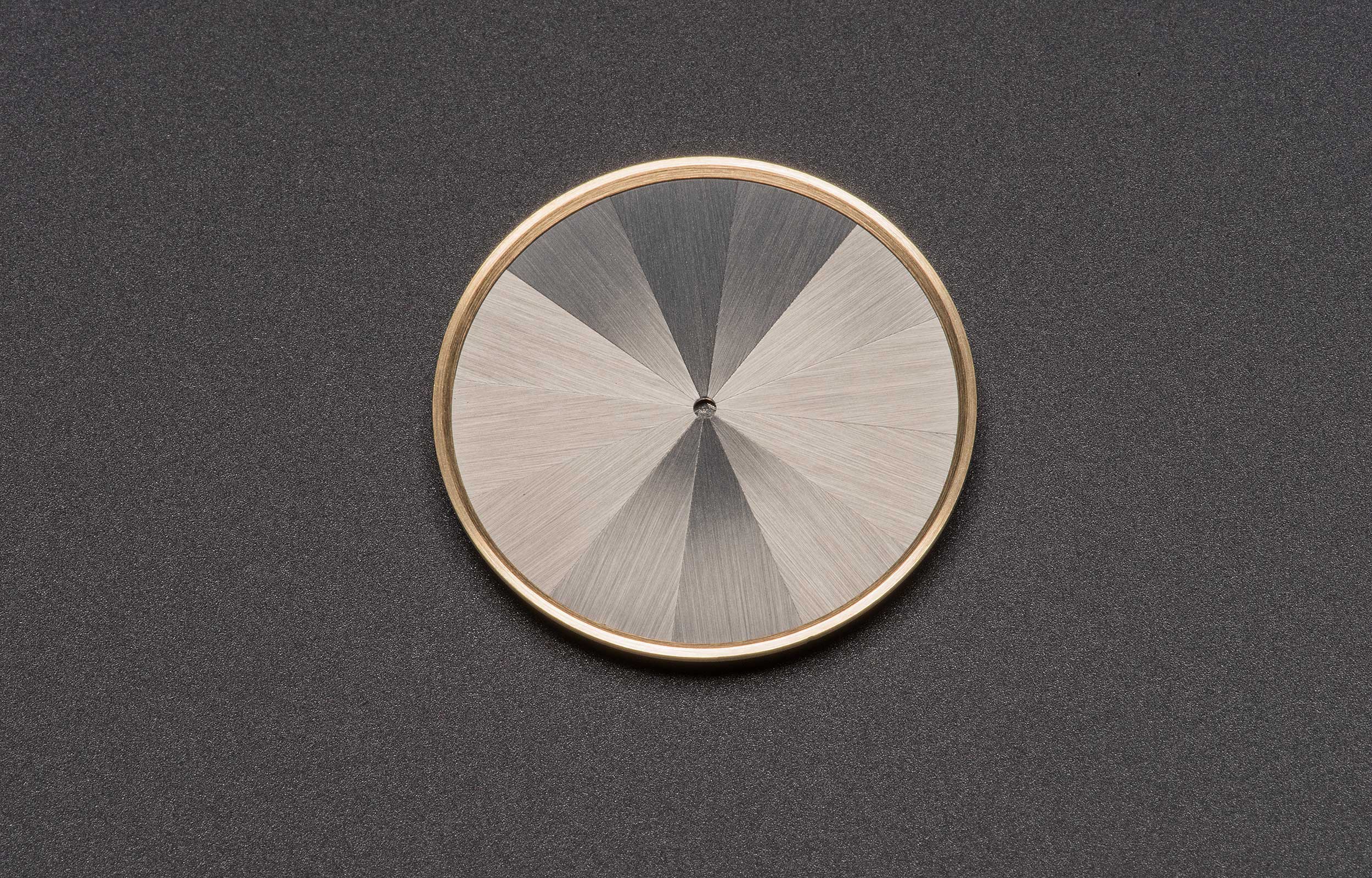

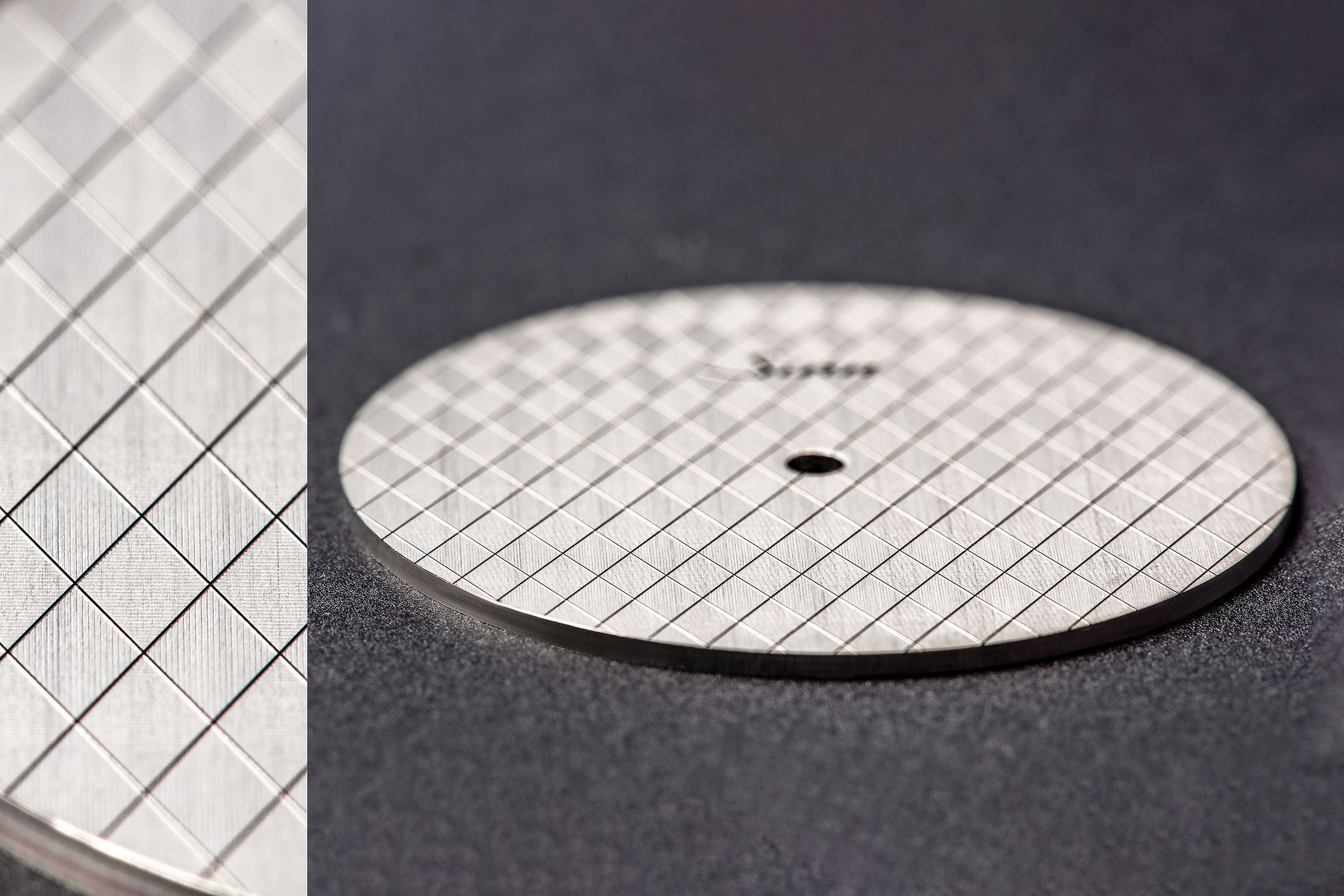

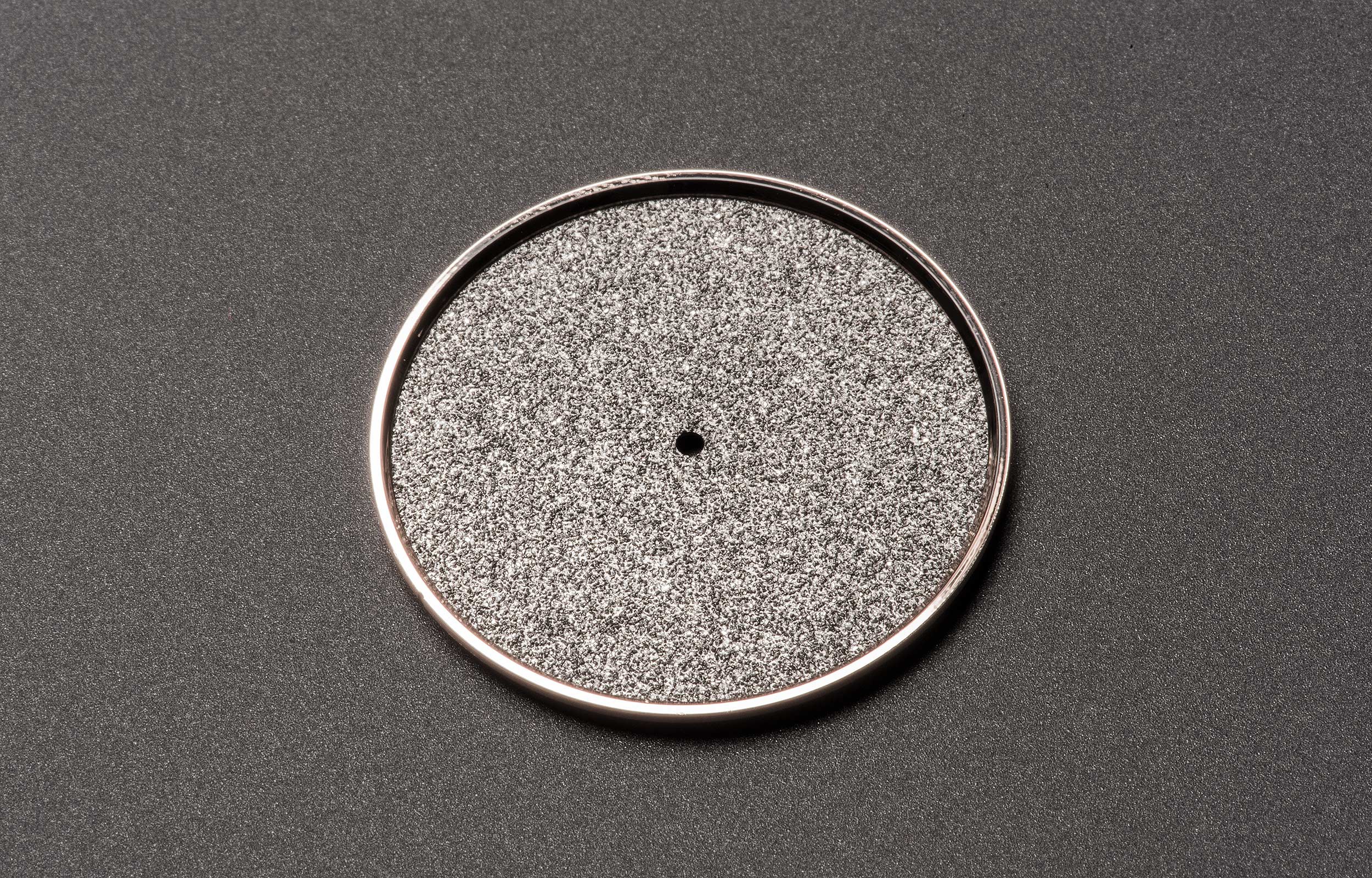

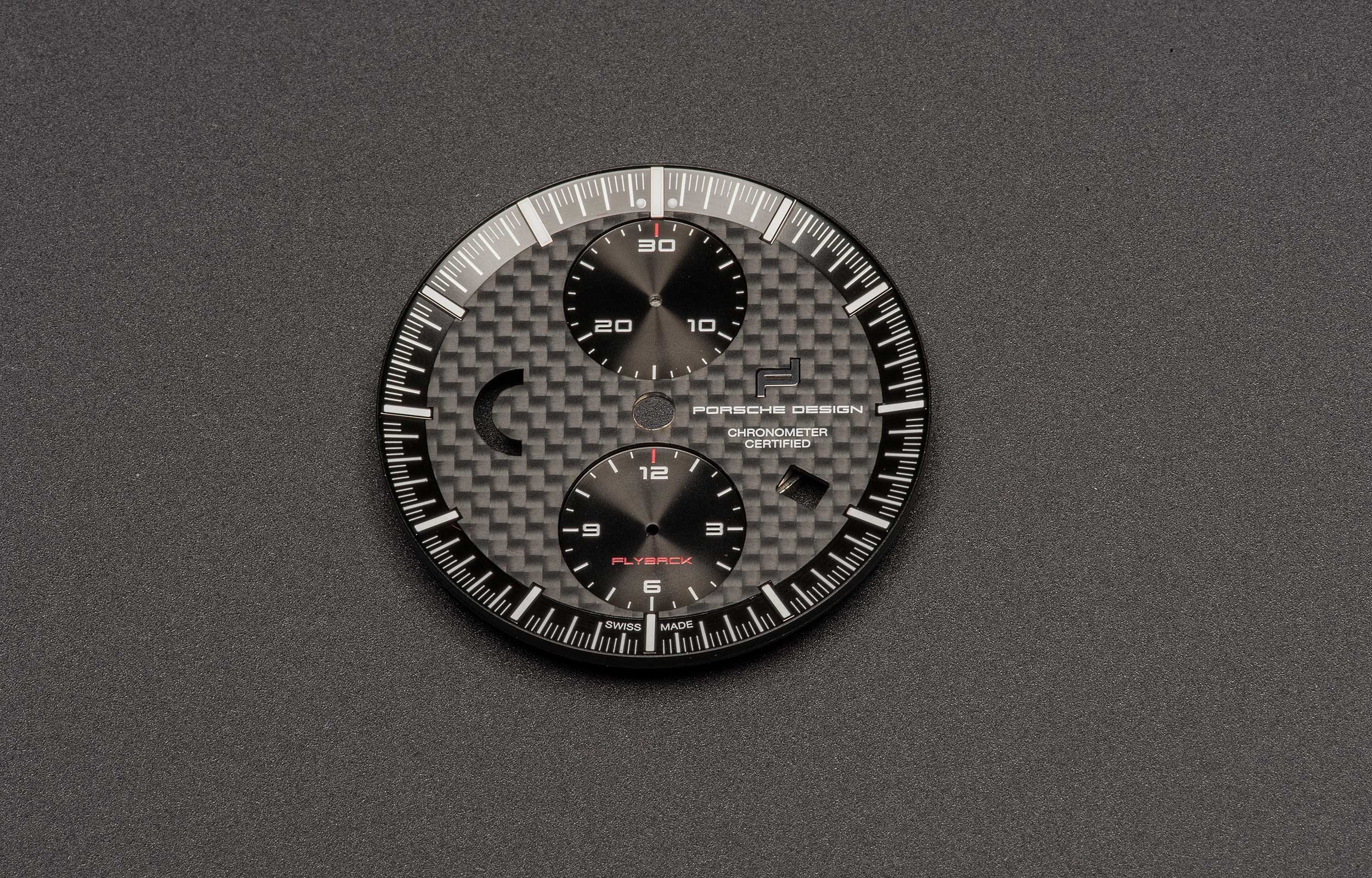

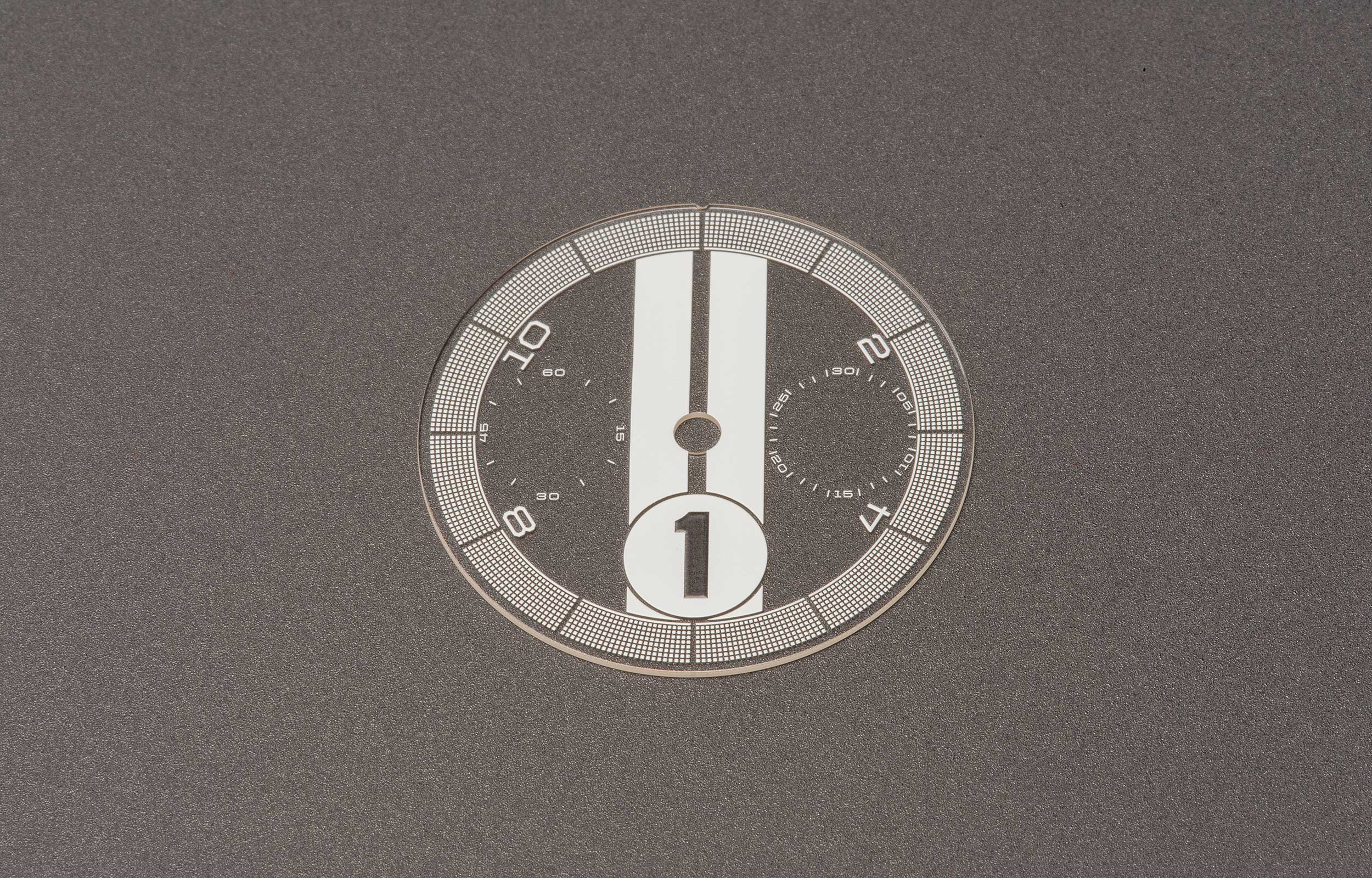

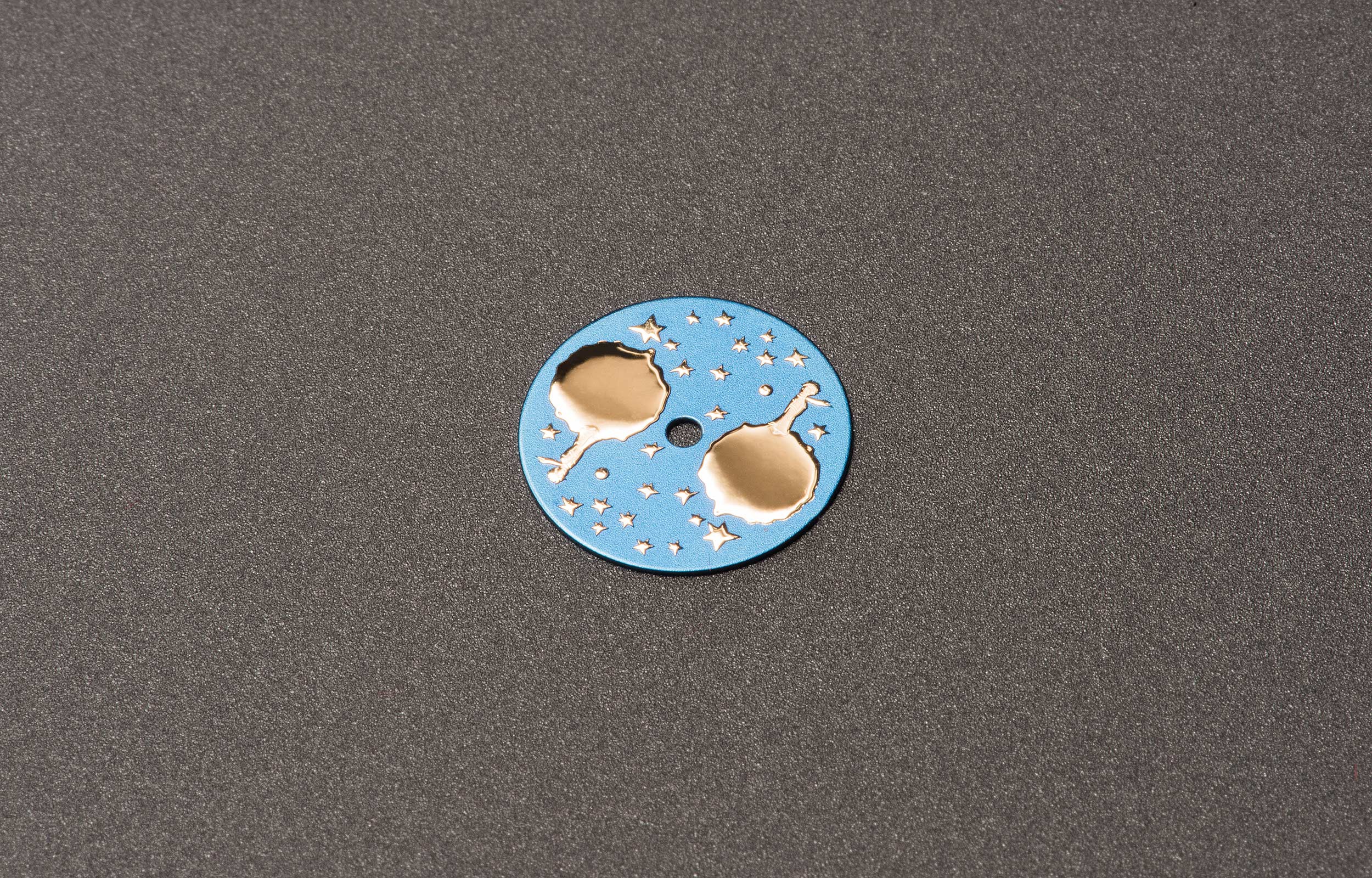

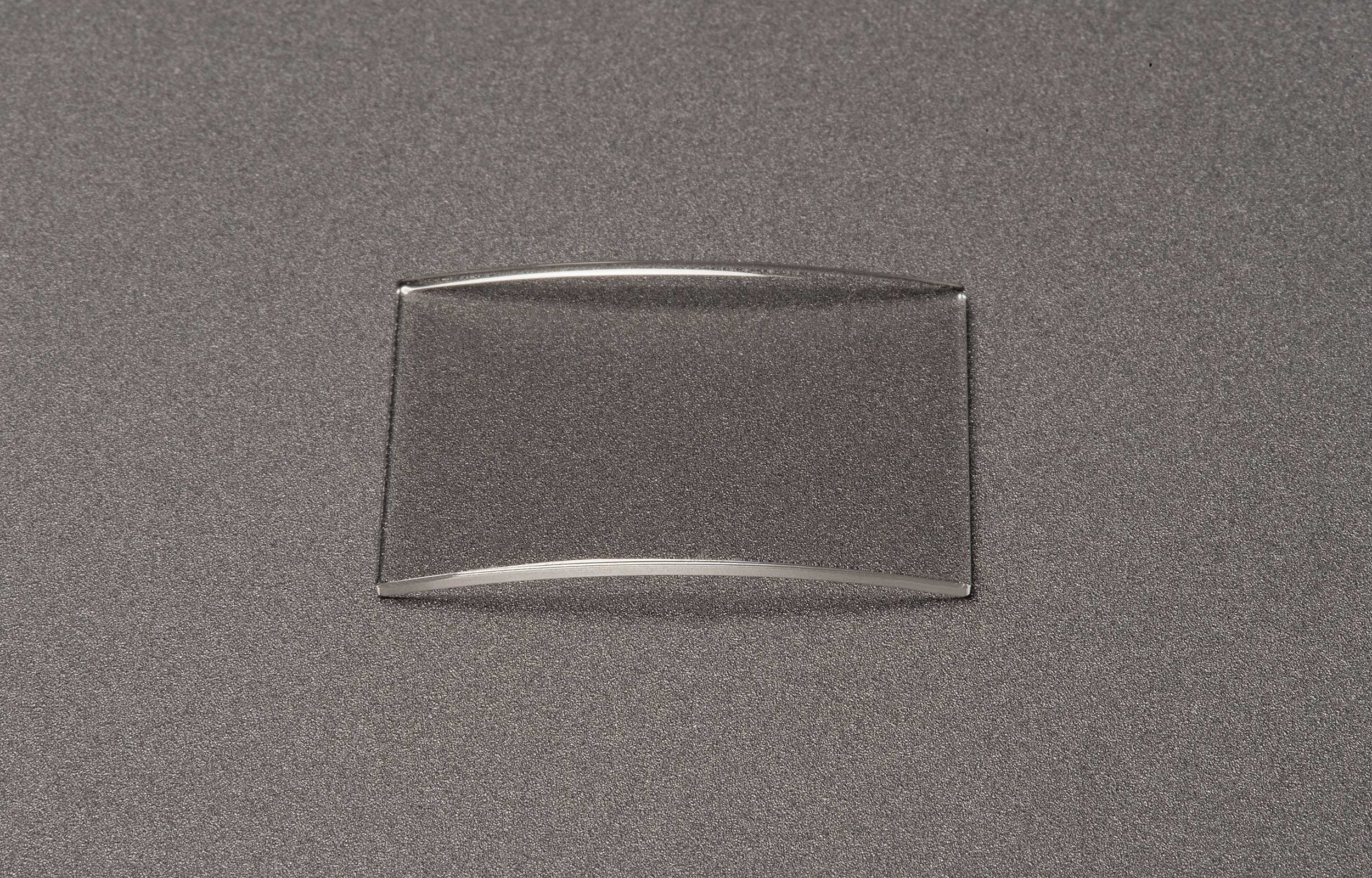

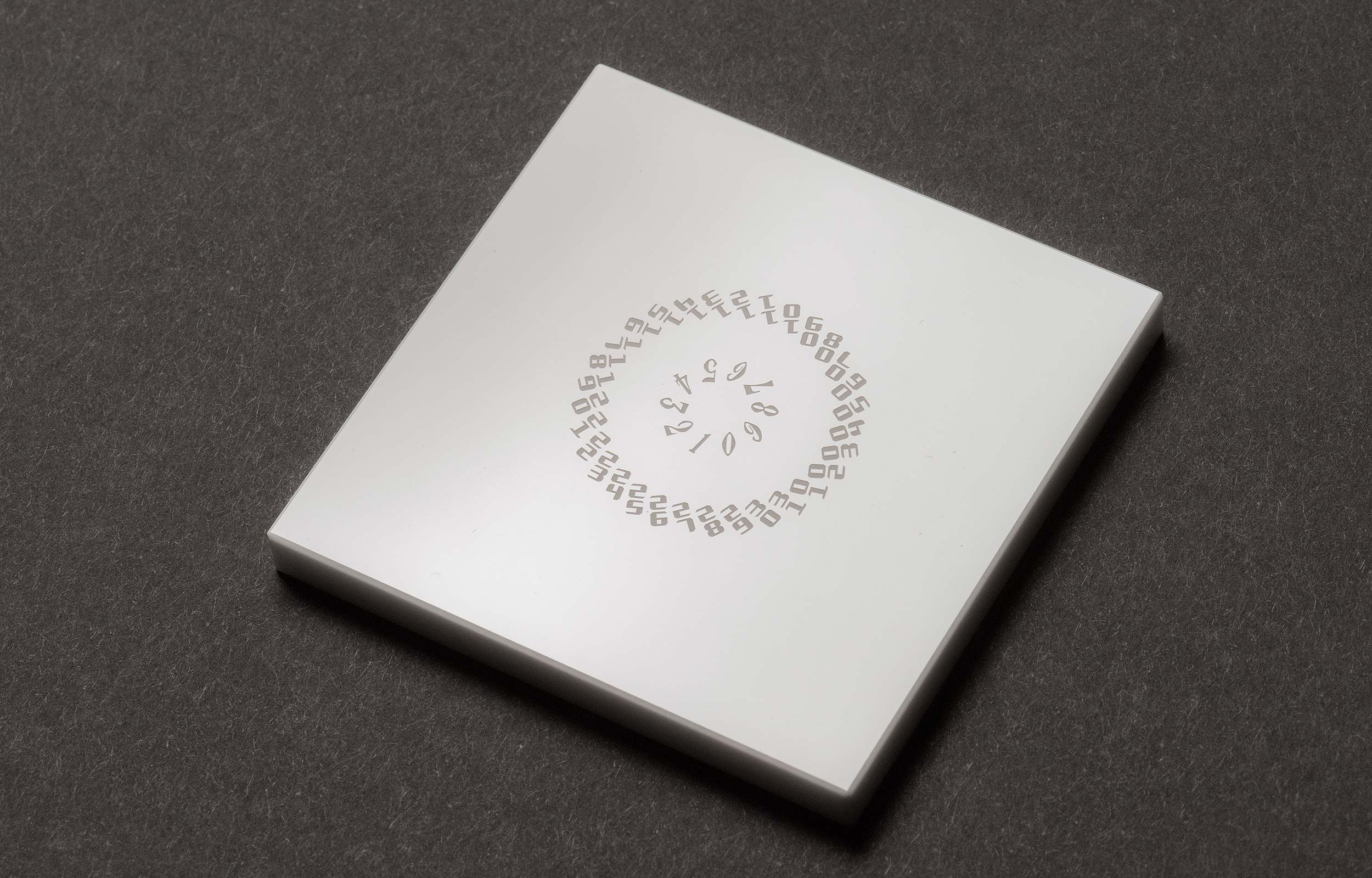

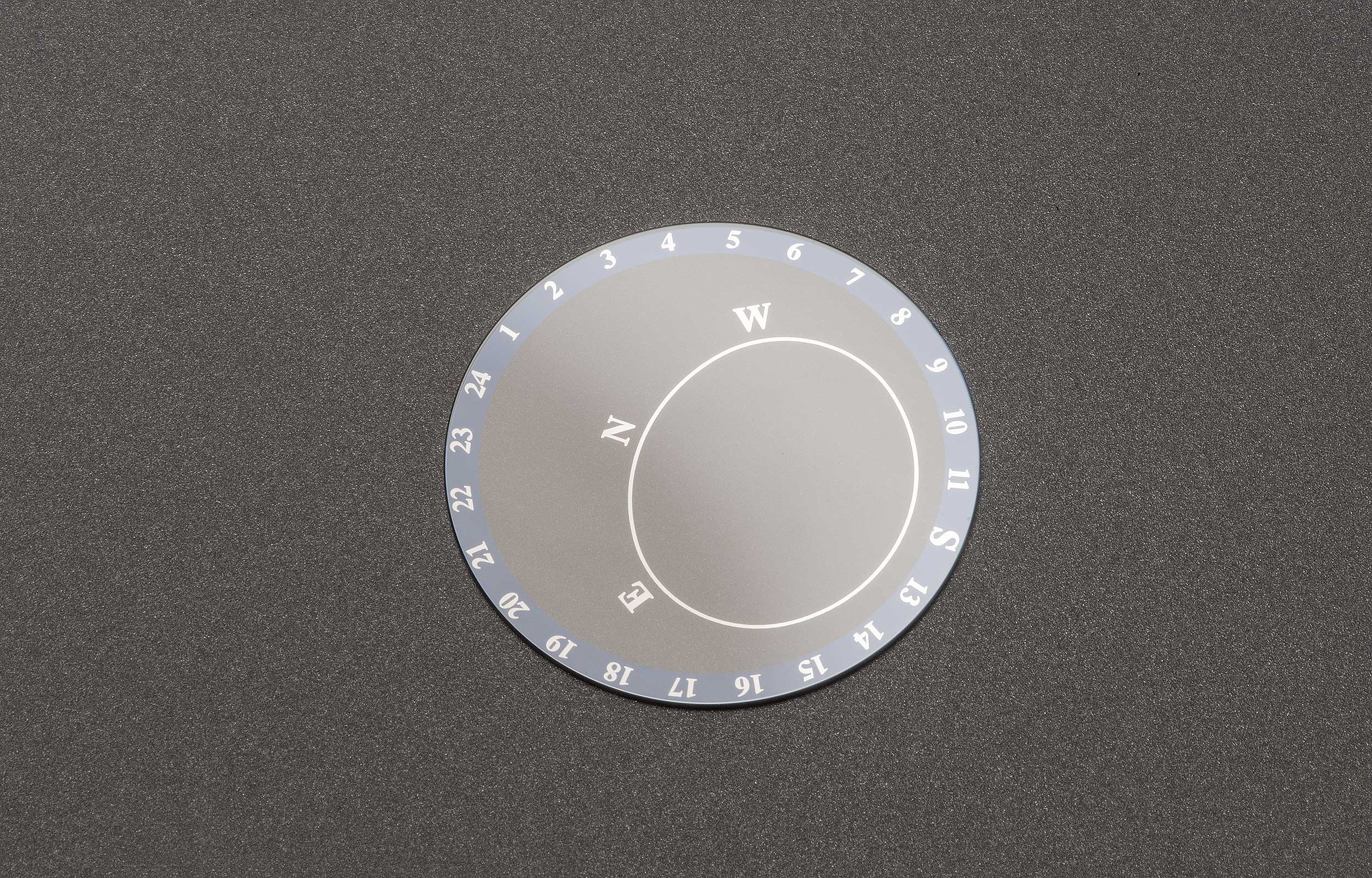

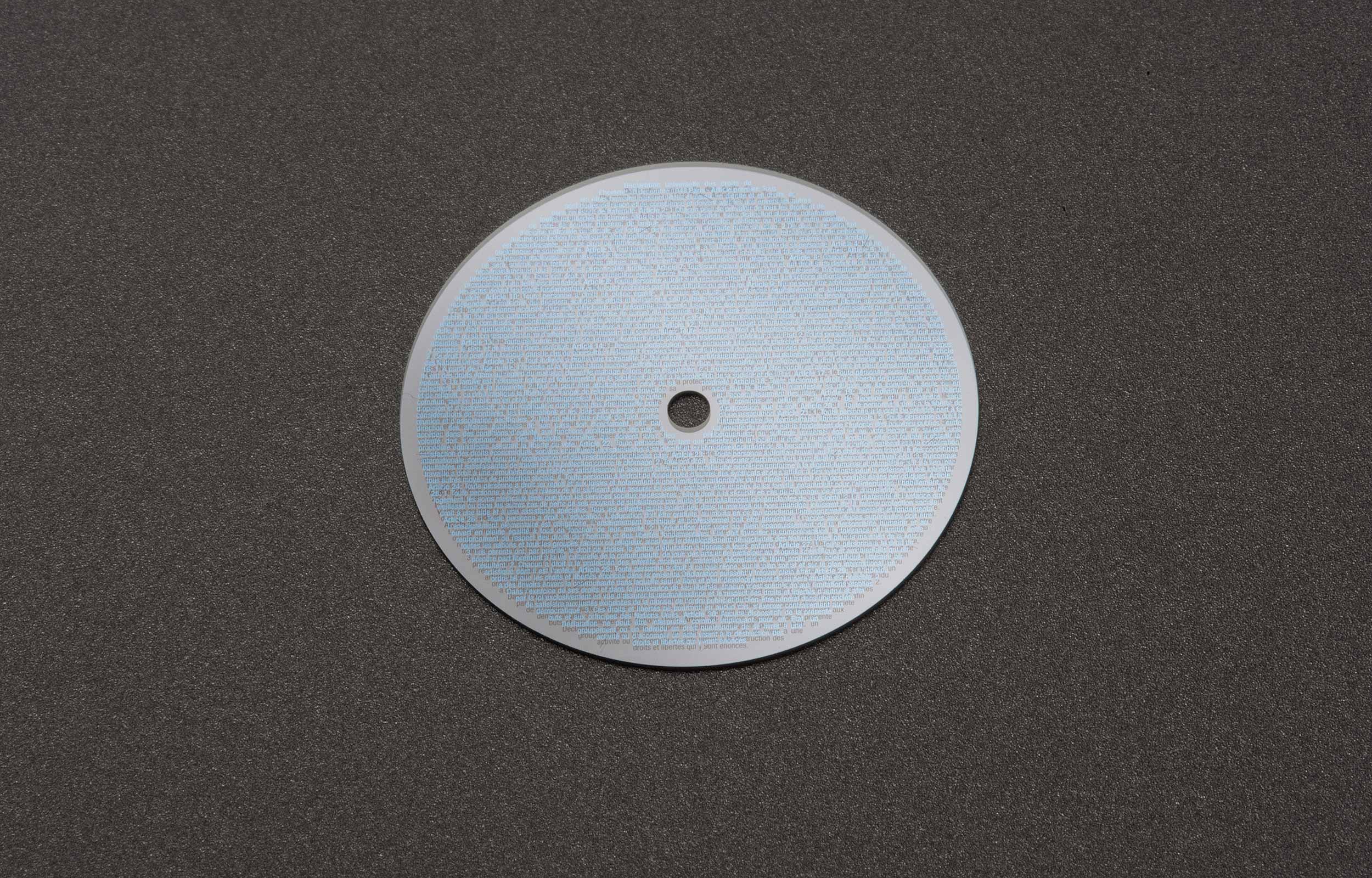

A watch industry stalwart for over seven decades, Blösch AG's core business centers on developing and depositing decorative and functional coatings. We specialize in combining a range of technologies, such as PVD, PECVD and galvanics, to coat exterior watch components and movement components.