Medical devices

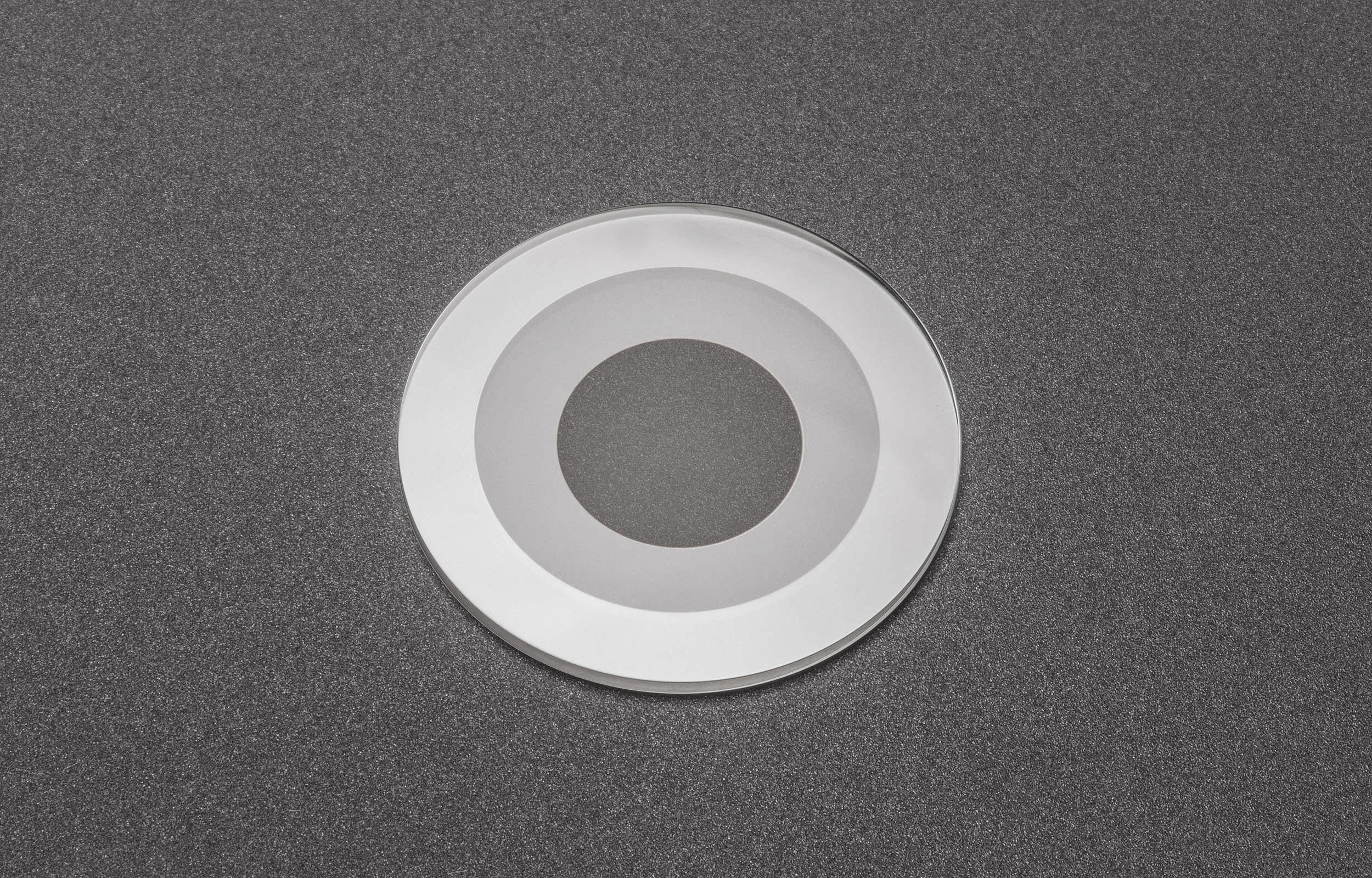

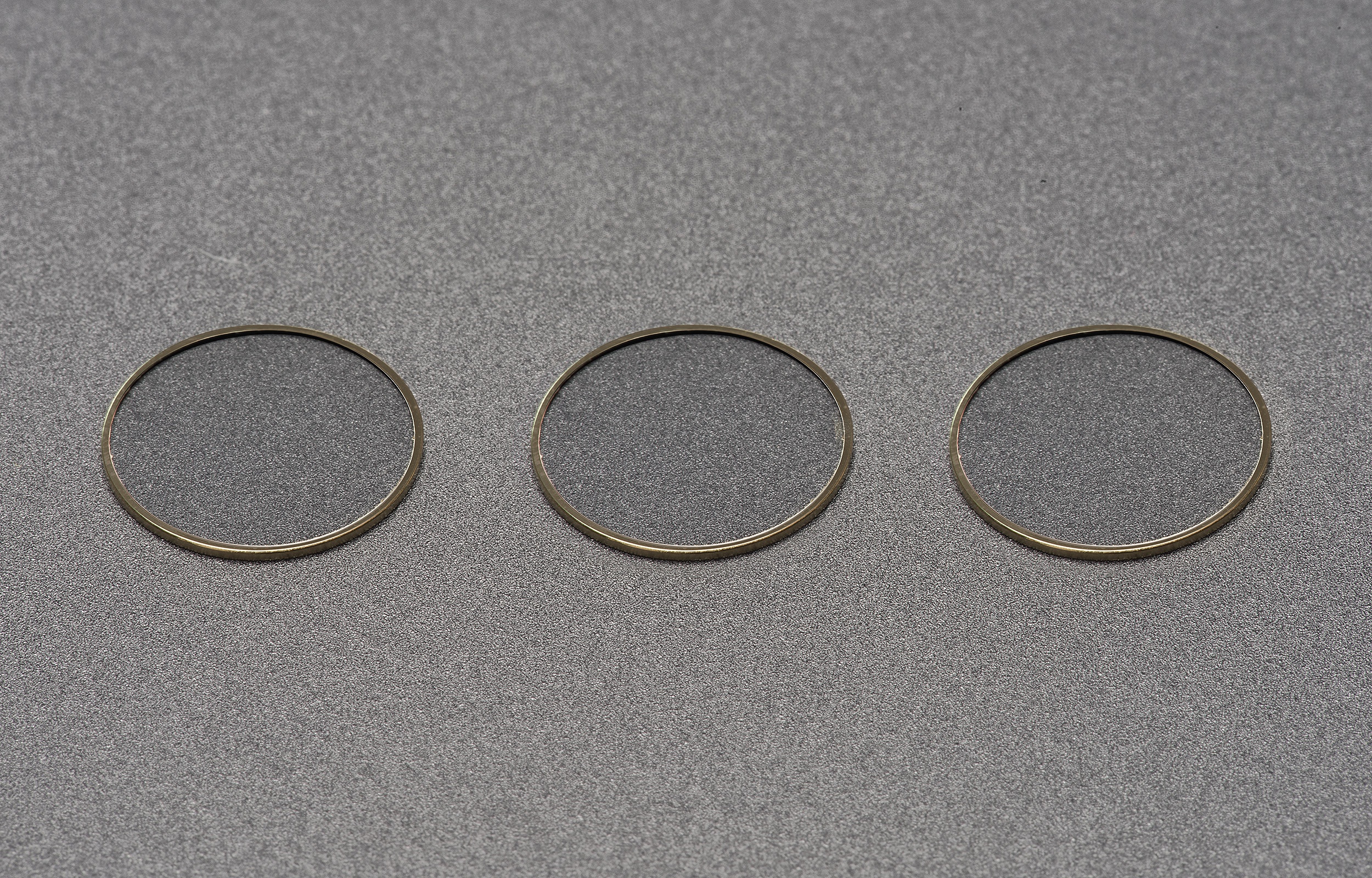

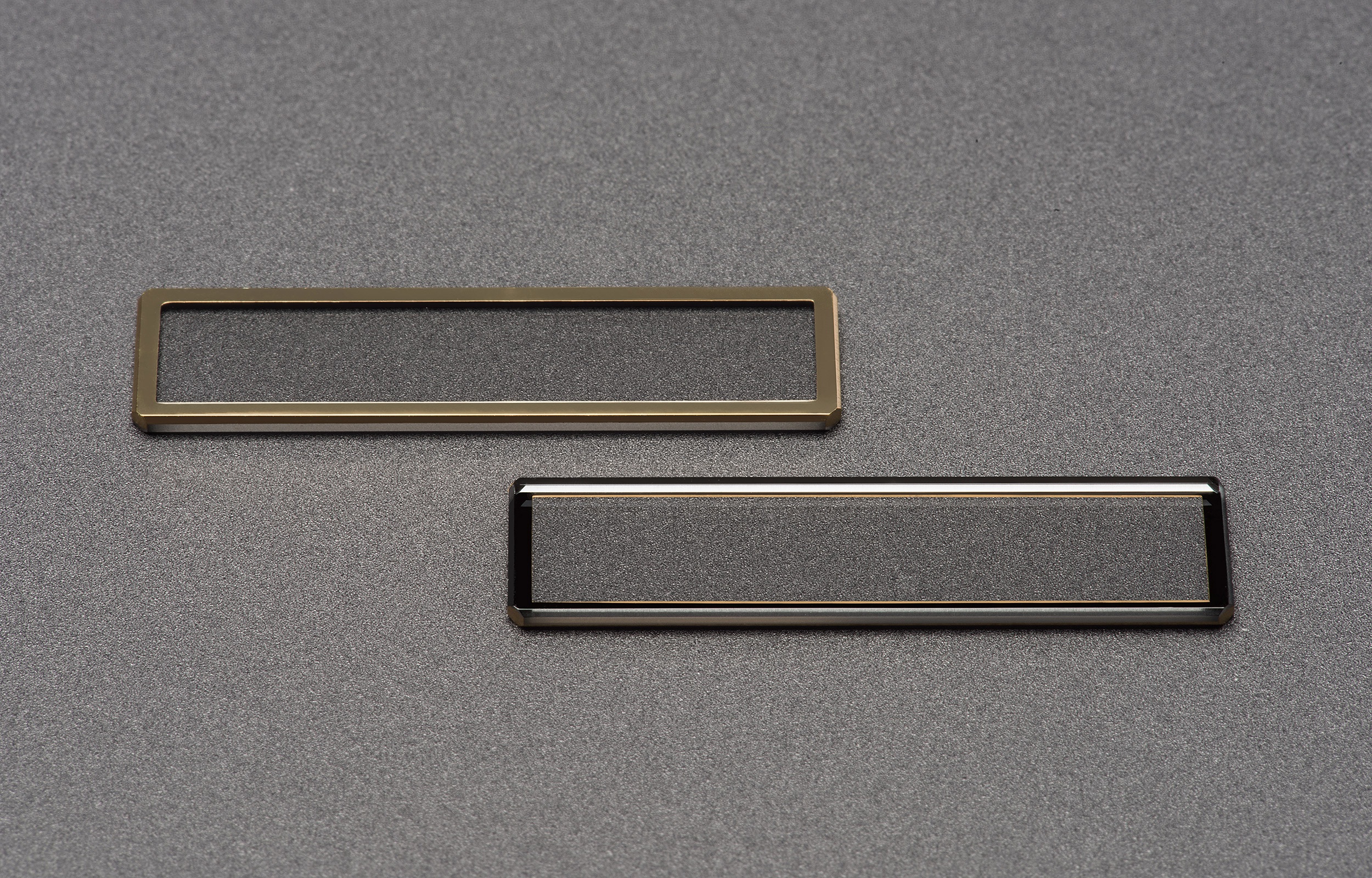

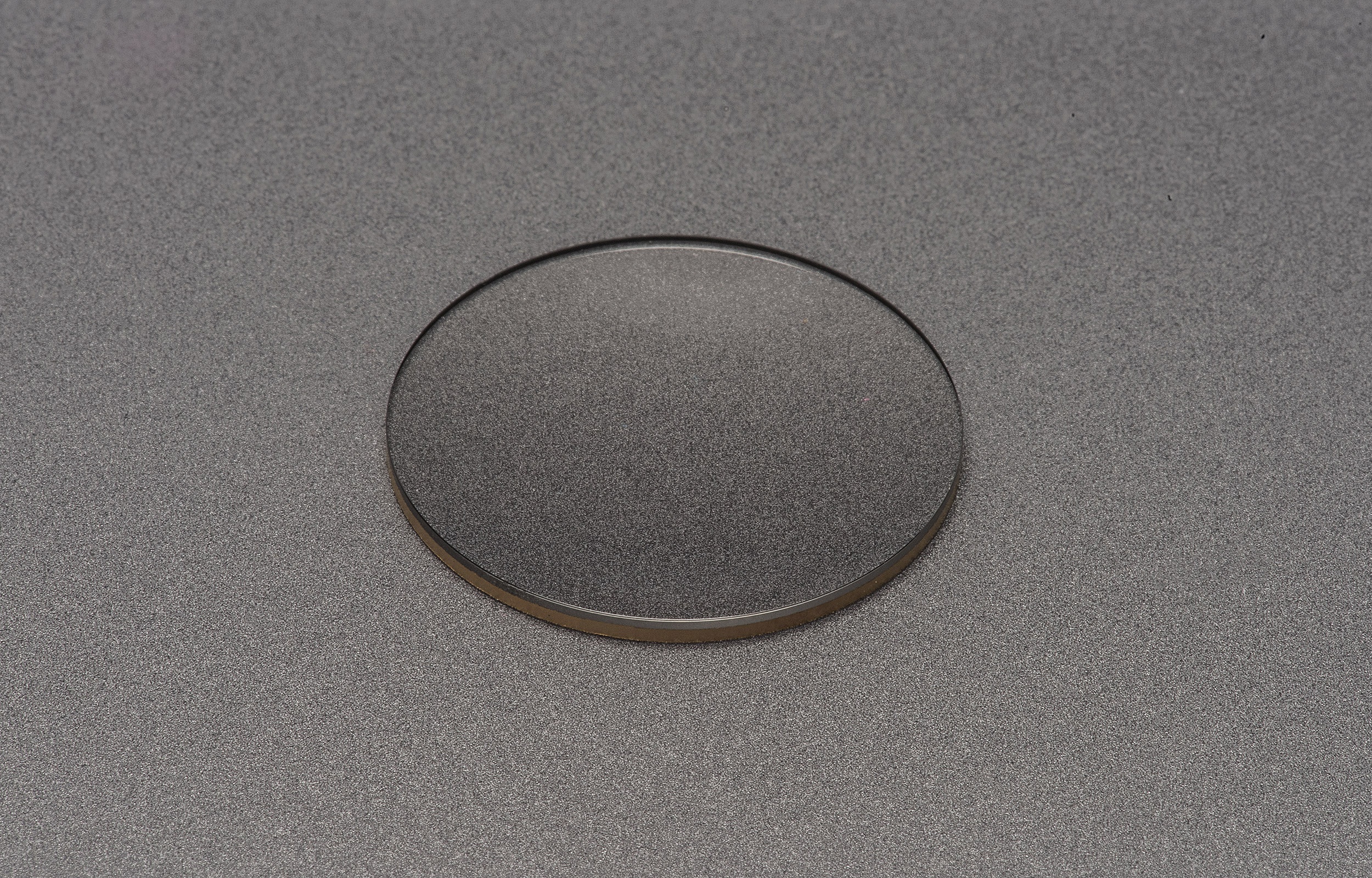

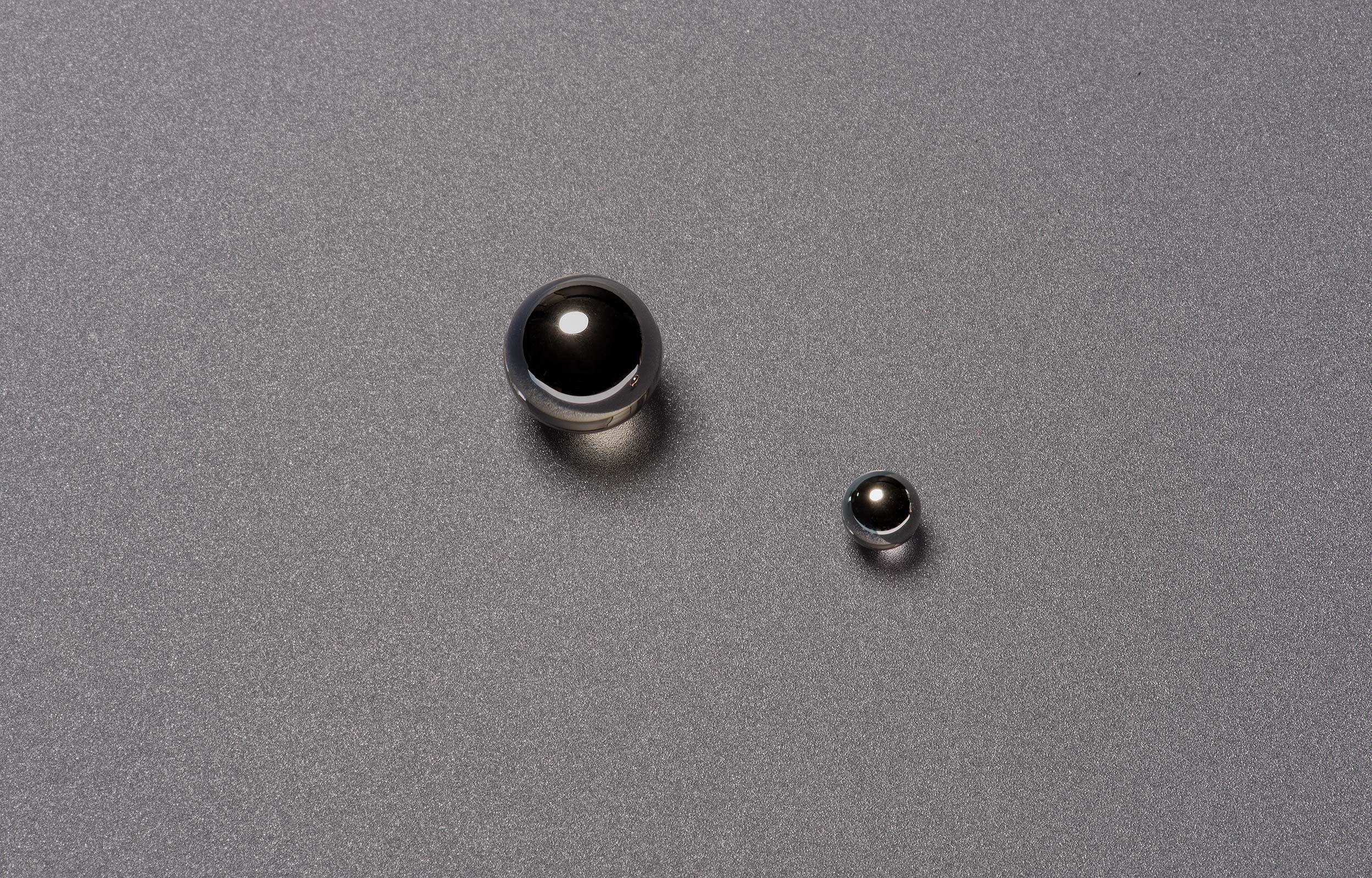

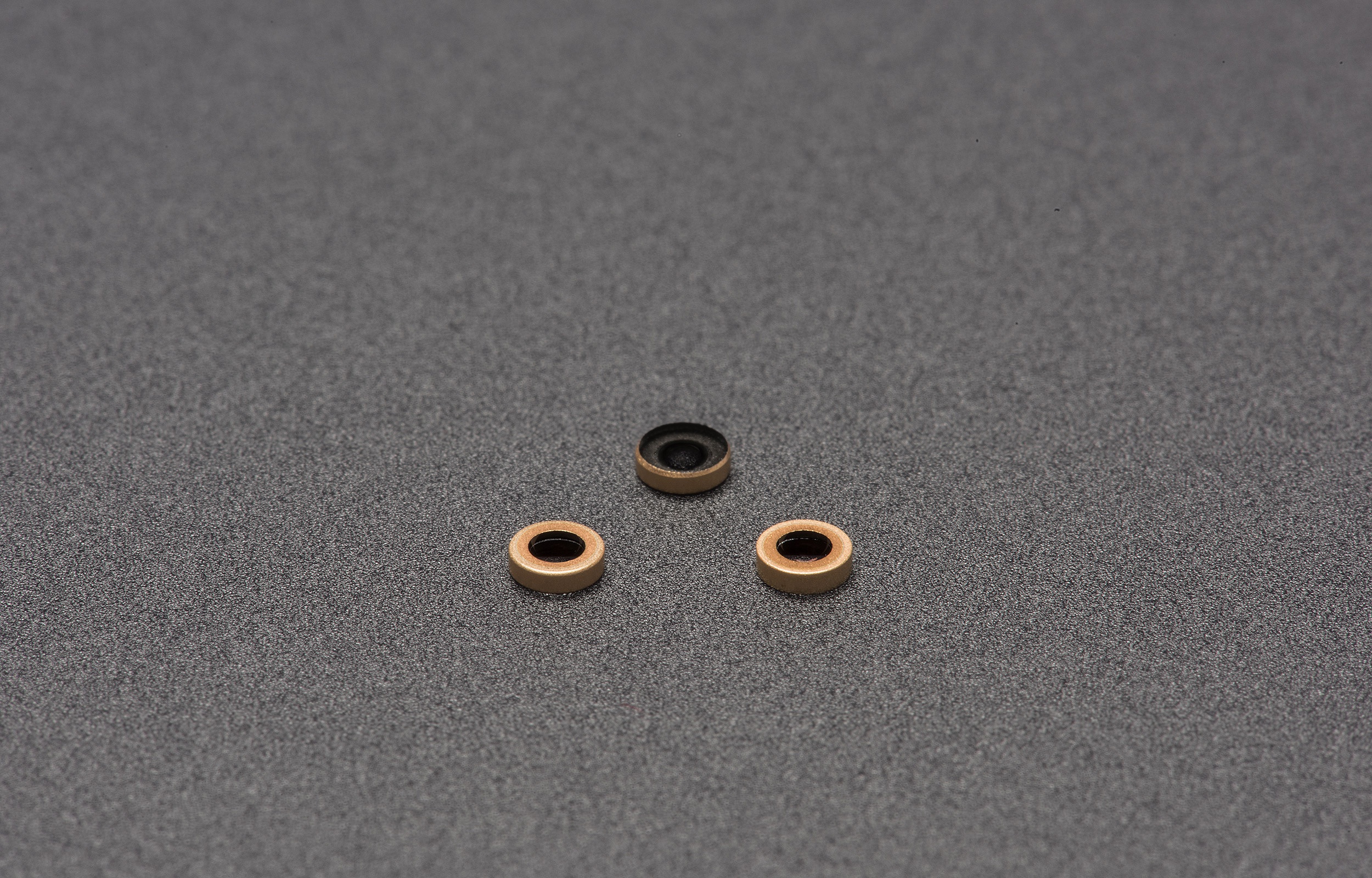

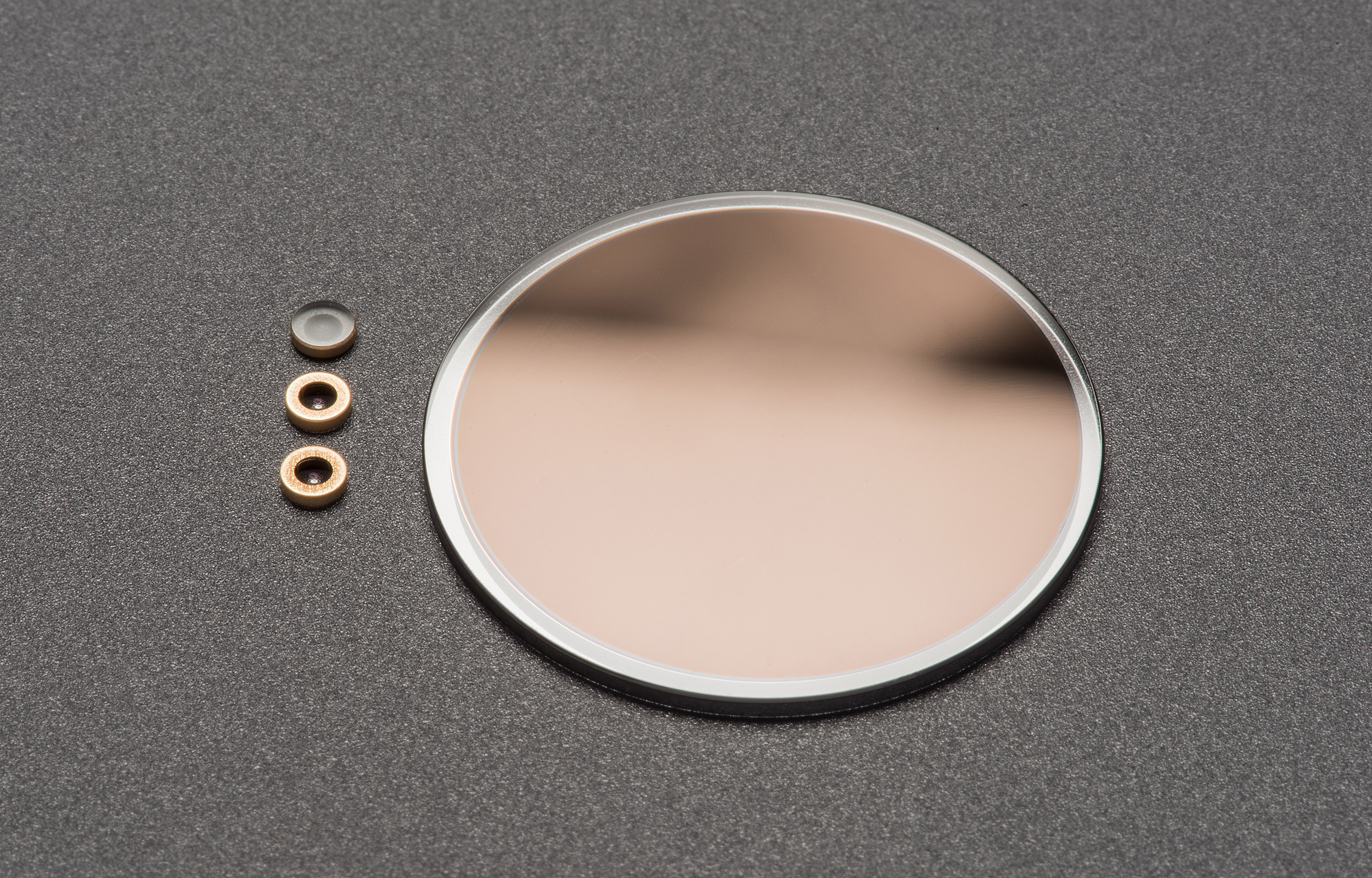

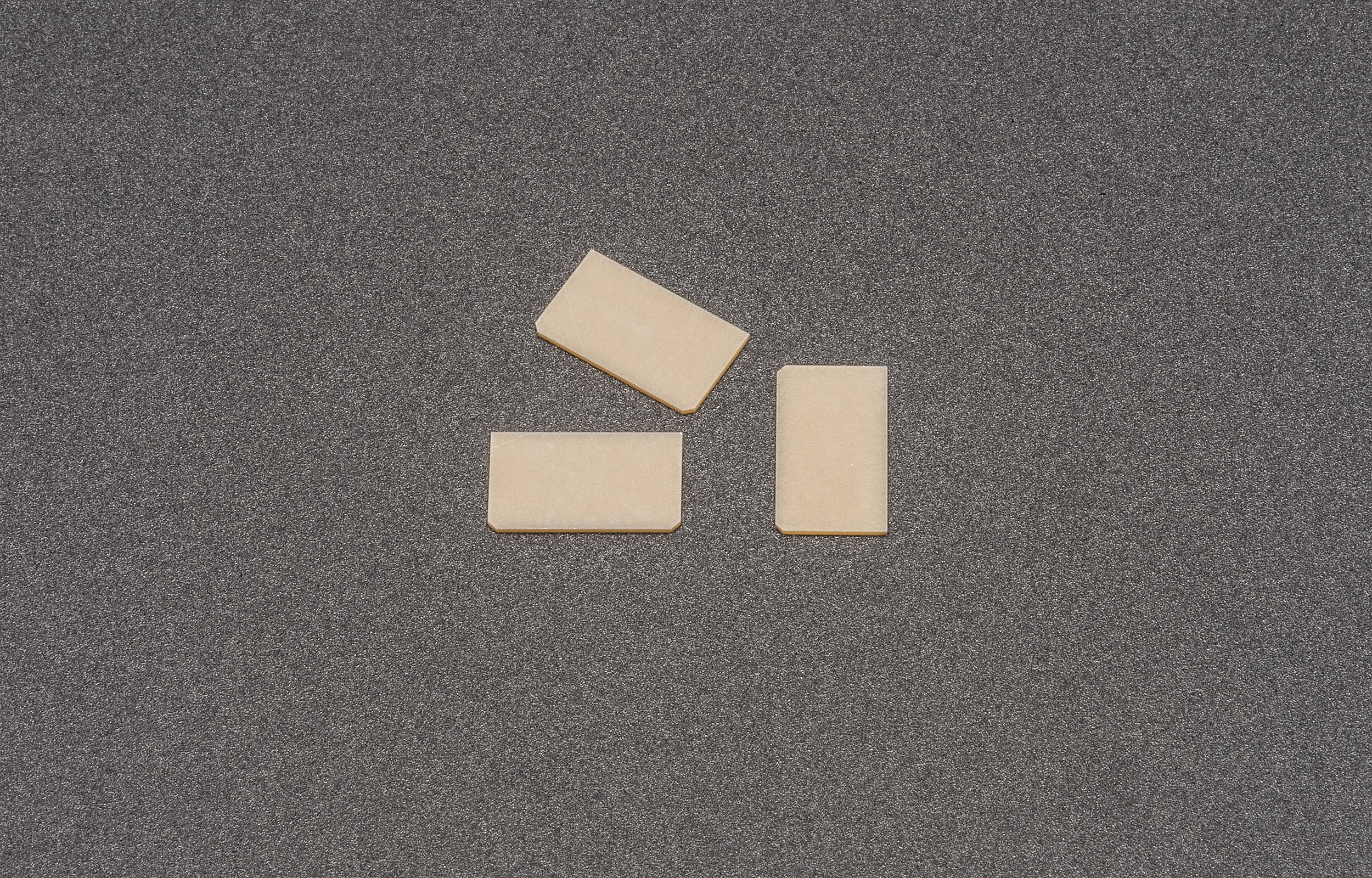

For more than 20 years we have been successfully using our coating know-how in the medical device market. Our core competence lies in the integration of sapphire windows into optical medical analysis devices (hermetic packaging), for example for endoscopy. We produce among others solderable coatings and sterilization-resistant optical filters for camera systems.