Optics and sensors

Blösch's high-end coating solutions have many applications in the markets of Optics & Sensors.

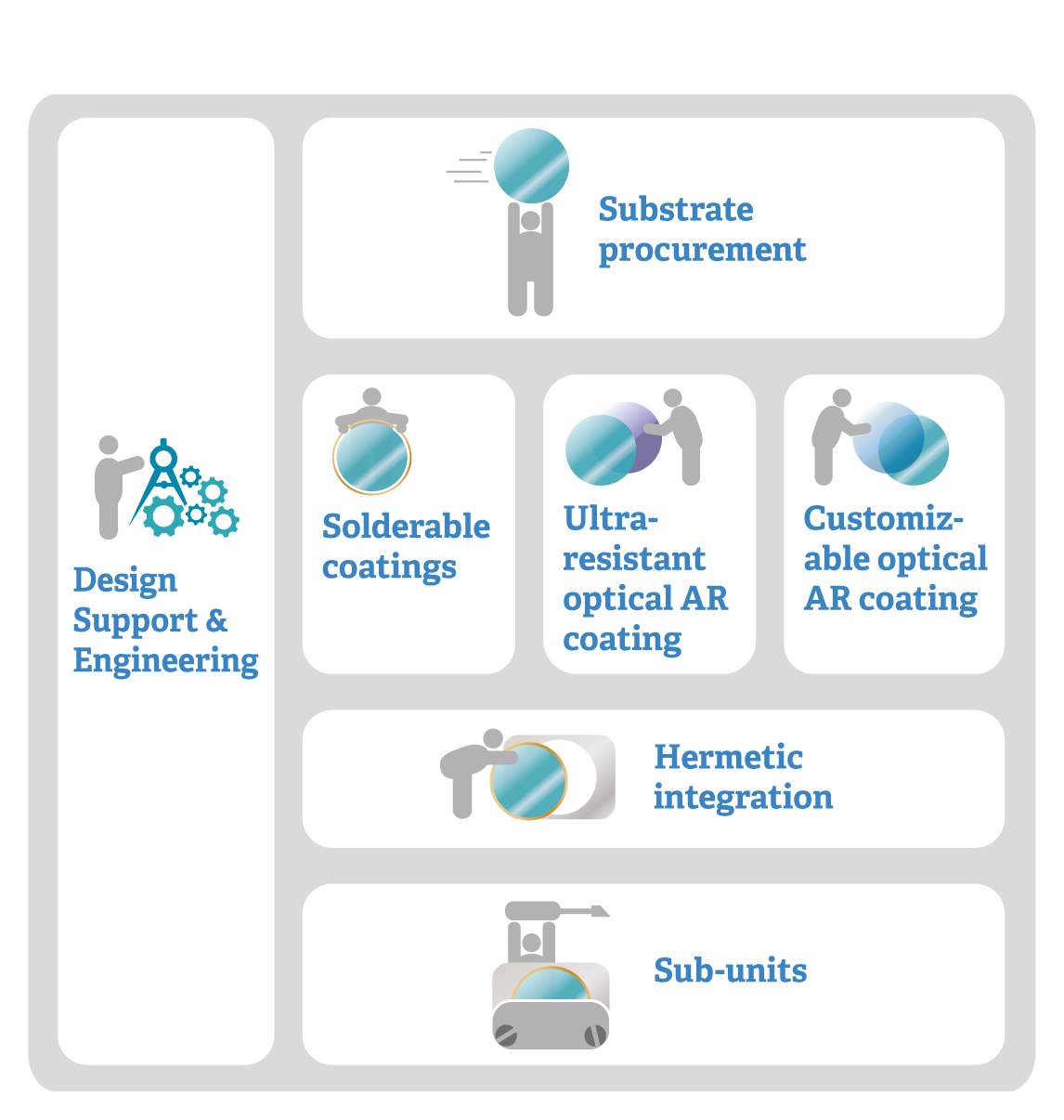

Customers value in particular Blösch's:

- Solution-oriented engineering

- Wide portfolio of technical capabilities

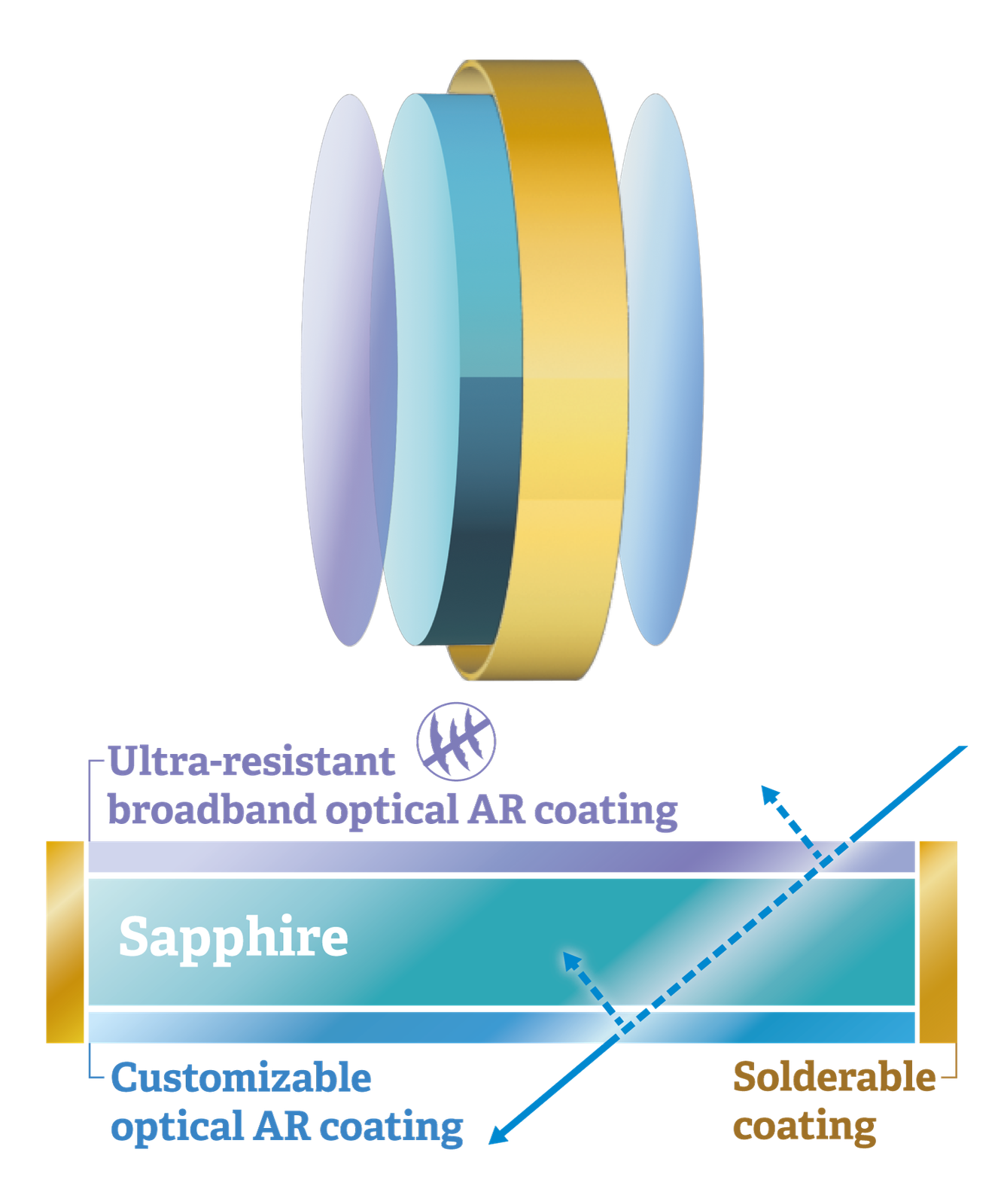

- In-house optical and metallic coating competences

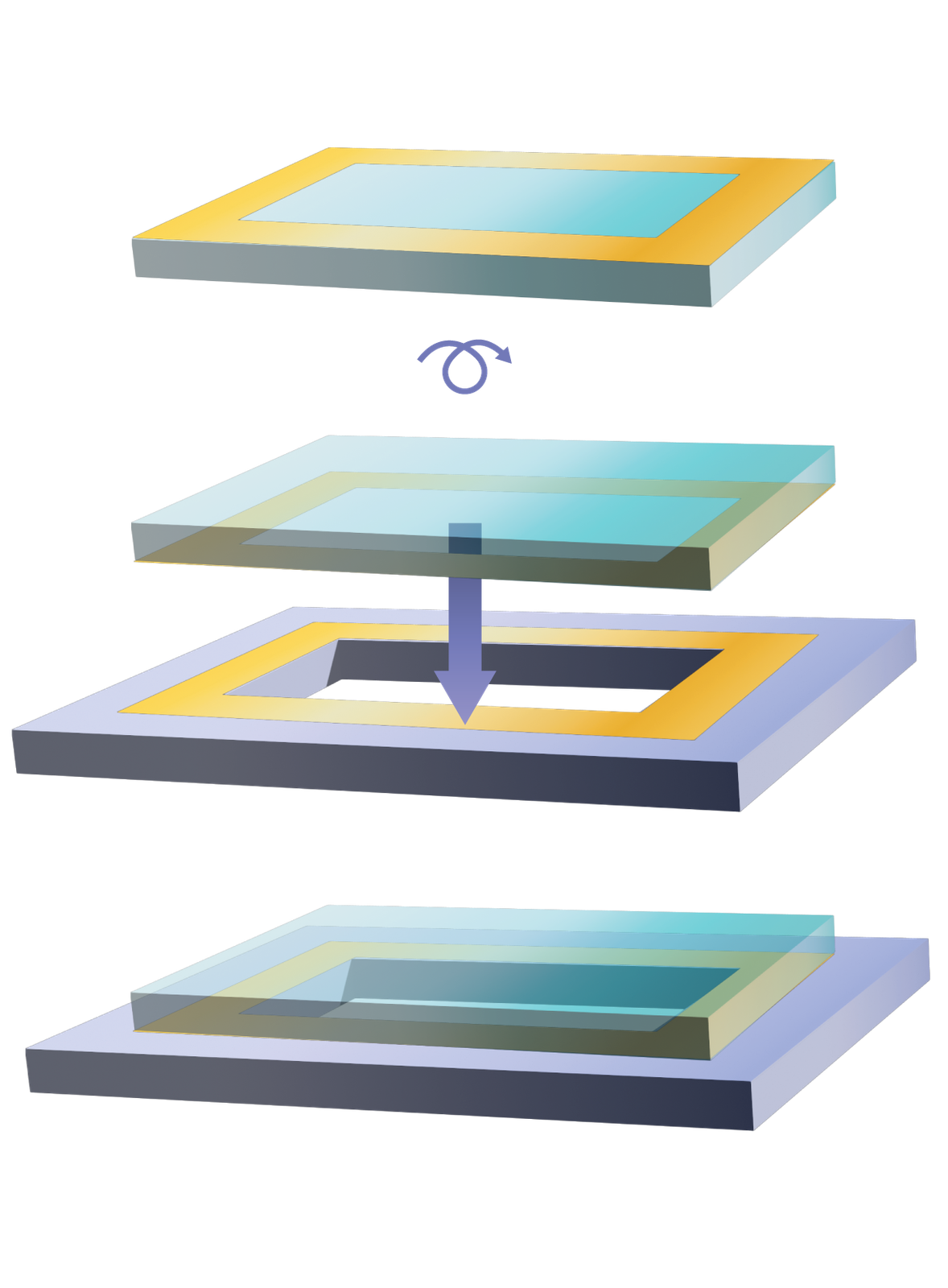

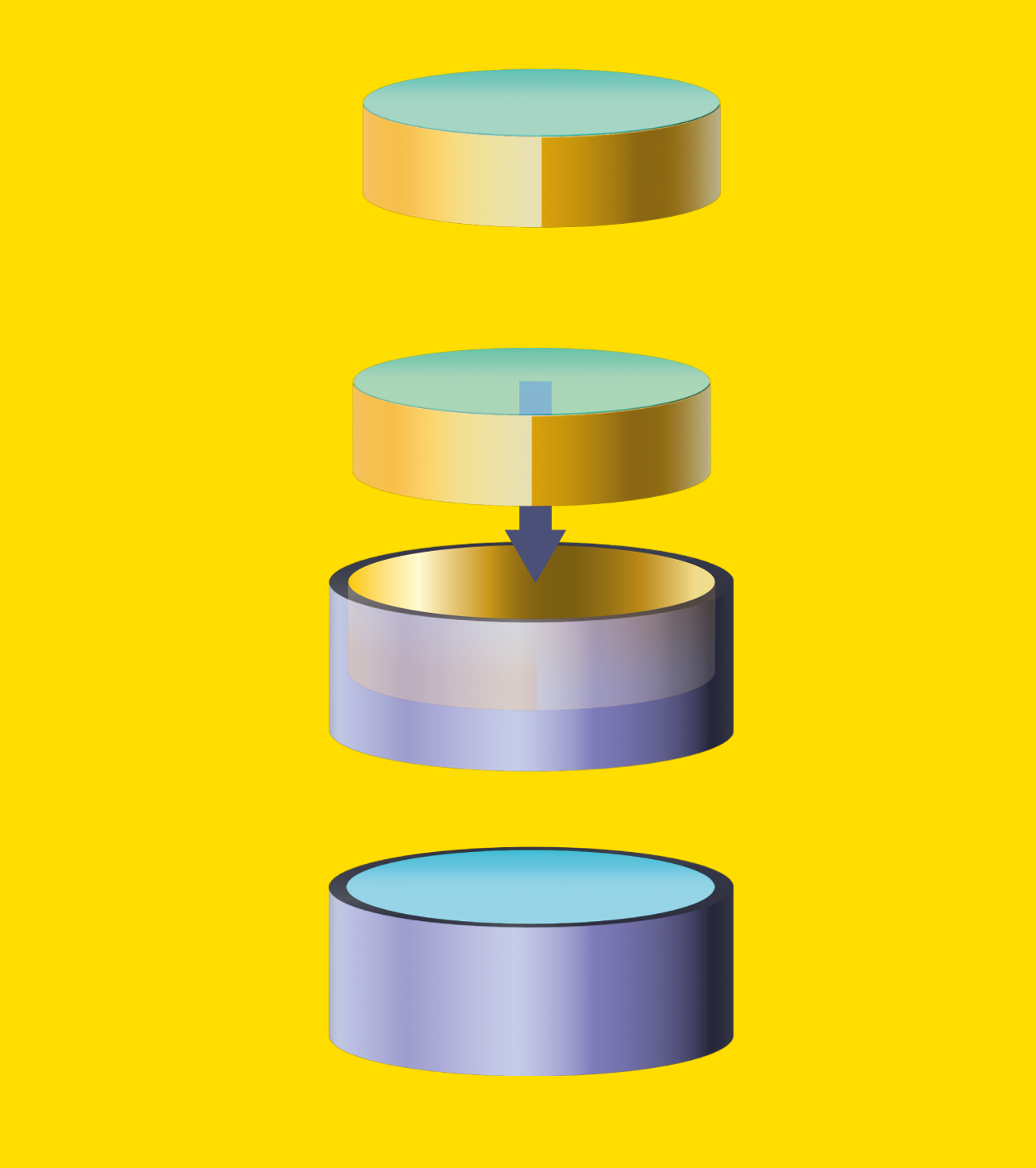

- Hermetic integration systems

- Test and qualification services

- Overall customer support